Nov 21, 2019

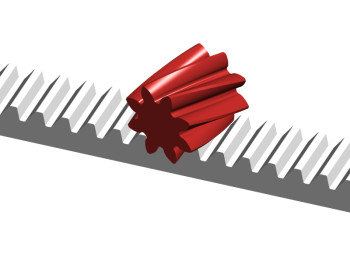

In vehicles, the transmission from the steering wheel to the wheels is often carried out by a rack and pinion drive. In standard industrial rack and pinion drives, the angle between the pinion axis and the rack is 90°. Due to installation conditions in the vehicle, however, the axis angle between pinion and rack usually has to be adjusted. This results in a crossed helical gear pairing, with the rack having an infinitely large number of teeth.

This calculation option - crossed helical gear with rack - is available as of the KISSsoft Release 2019 (module ZE7). The theory of calculating a crossed helical gear pair with geometry and strength according to Niemann has been extended for racks. This allows the strength, service life, sliding speeds and efficiency of such a drive to be determined. In a 3D representation with a skin model, the pairing can be rolled and the contact pattern can be checked.

Such mechanisms are often used for steering systems, especially in the automotive industry. By entering the coefficient of friction and calculating the sliding speeds as well as the forces, the efficiency of the drive can be calculated and optimized.

If you would like to learn more about this topic, please visit us from 10 to 11 December 2019 at the Transmission Symposium in Berlin, booth G11. The International CTI Symposium is the international industry event in Europe for all who are interested in the latest research results in the automotive sector. We look forward to your visit!